Manufacturing as Code is the Future, and the Future is Now

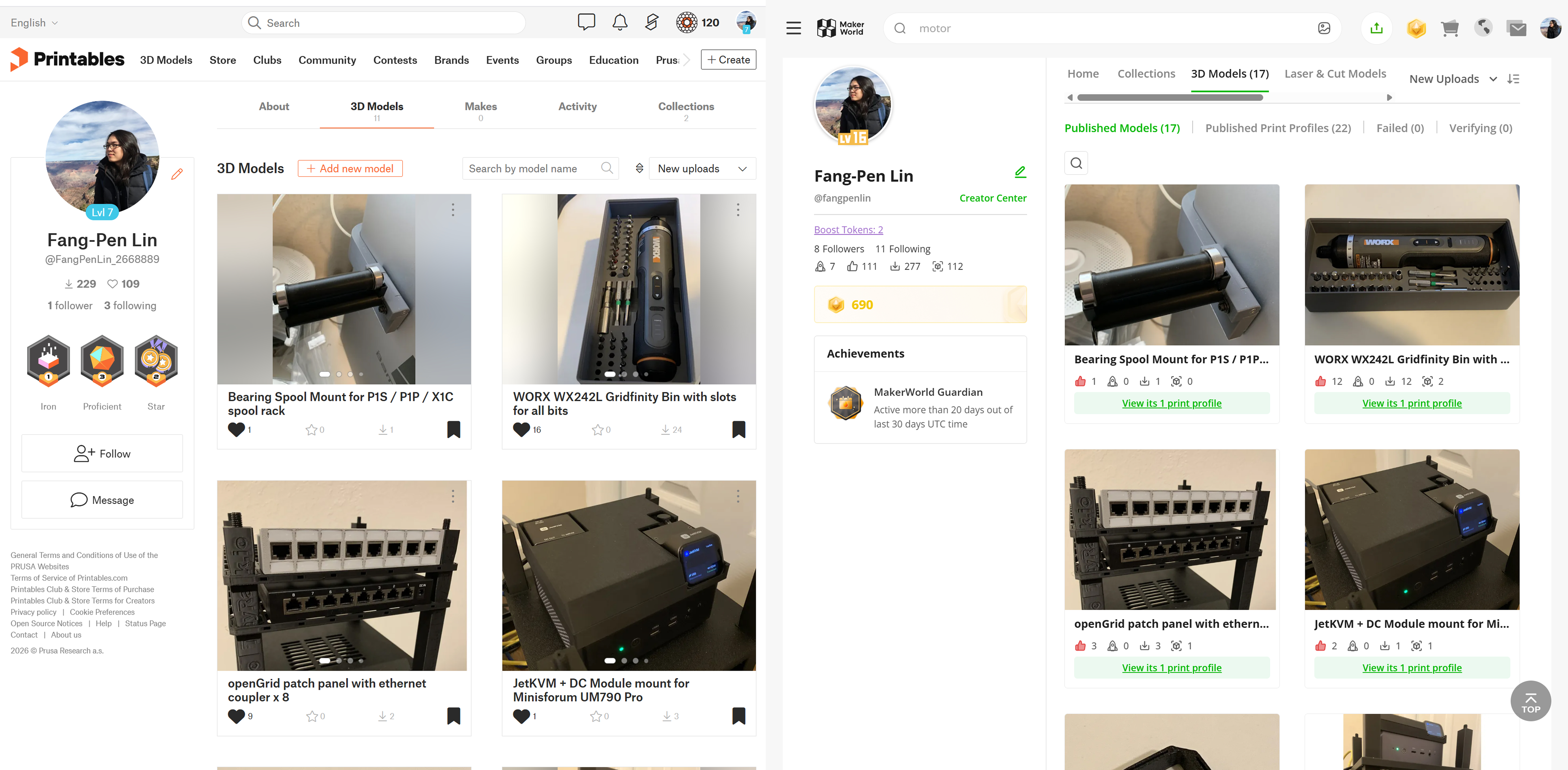

Since I started my journey with 3D printing, I have built and shared dozens of 3D printable models to the public. Surely, TinyRack is one of them. You can find them on my MakerWorld profile here or on my Printables profile here.

So far, I have really enjoyed the process of designing and printing the models. If there’s anything I’ve experienced that feels most like it came out of science fiction, it’s 3D printing technology. When you realize that the physical form of objects can be defined by digital bits, it opens up unbounded possibilities for what we can do with the technology.

The more I design and print, the more I realize that while the printing process takes time, it runs smoothly in the background. But for design, it’s a whole different story. More often than not, it takes a huge amount of effort and countless iterations to design even for a simple snap-fit part. I often get lost when working with different revisions of the same part with slight differences. As printing technology becomes more and more mature, the bottleneck is not the printing anymore, it’s the design instead.

As a software engineer, I get very comfortable with writing code to define the behavior of a system. Setting up the CI/CD pipeline to automate the build and deployment process is also a common practice. While I work on my 3D printing projects, none of those exist. Then I wondered, given that now bits can shape atoms, why not use the same approach to build software for the physical world?

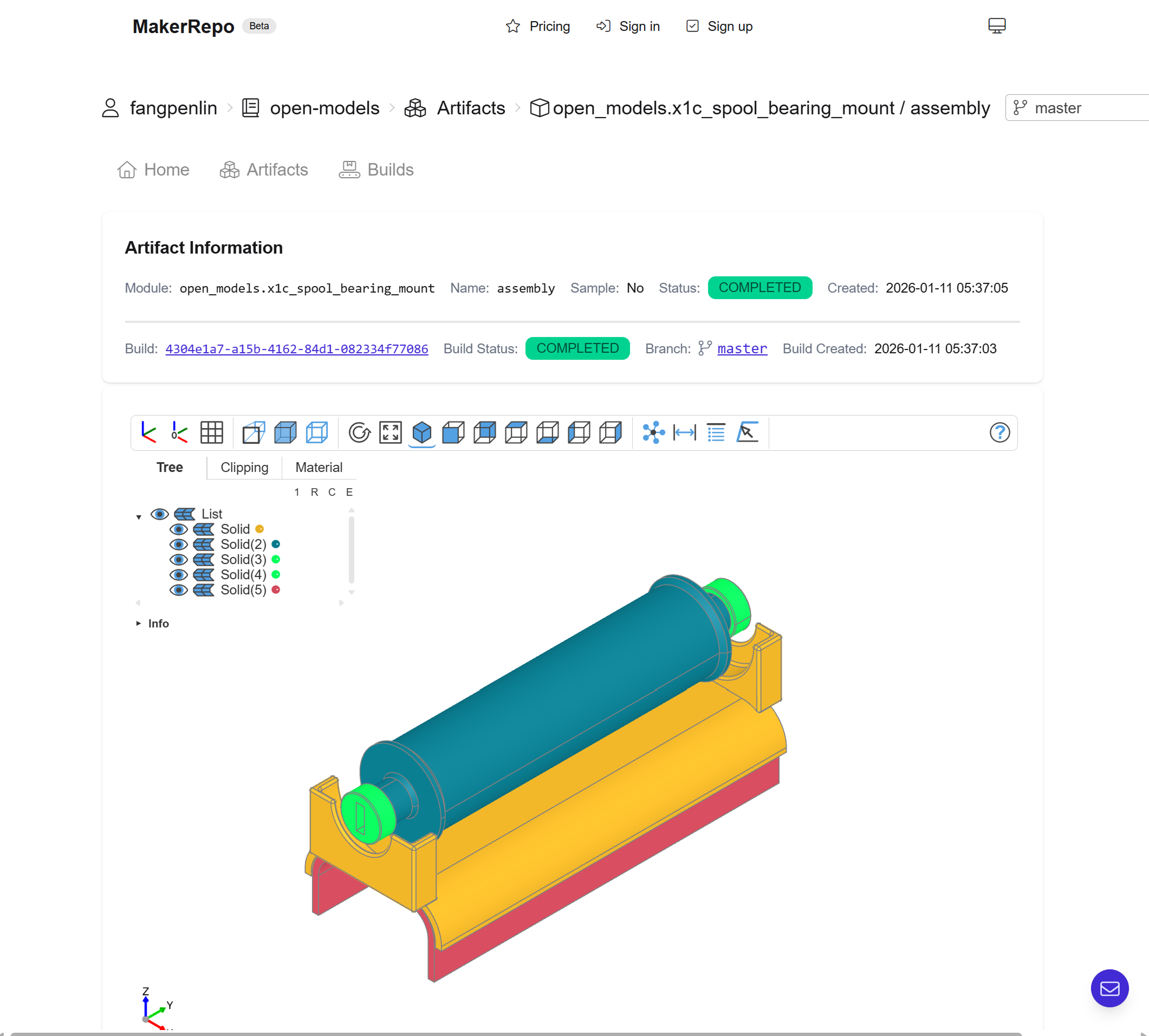

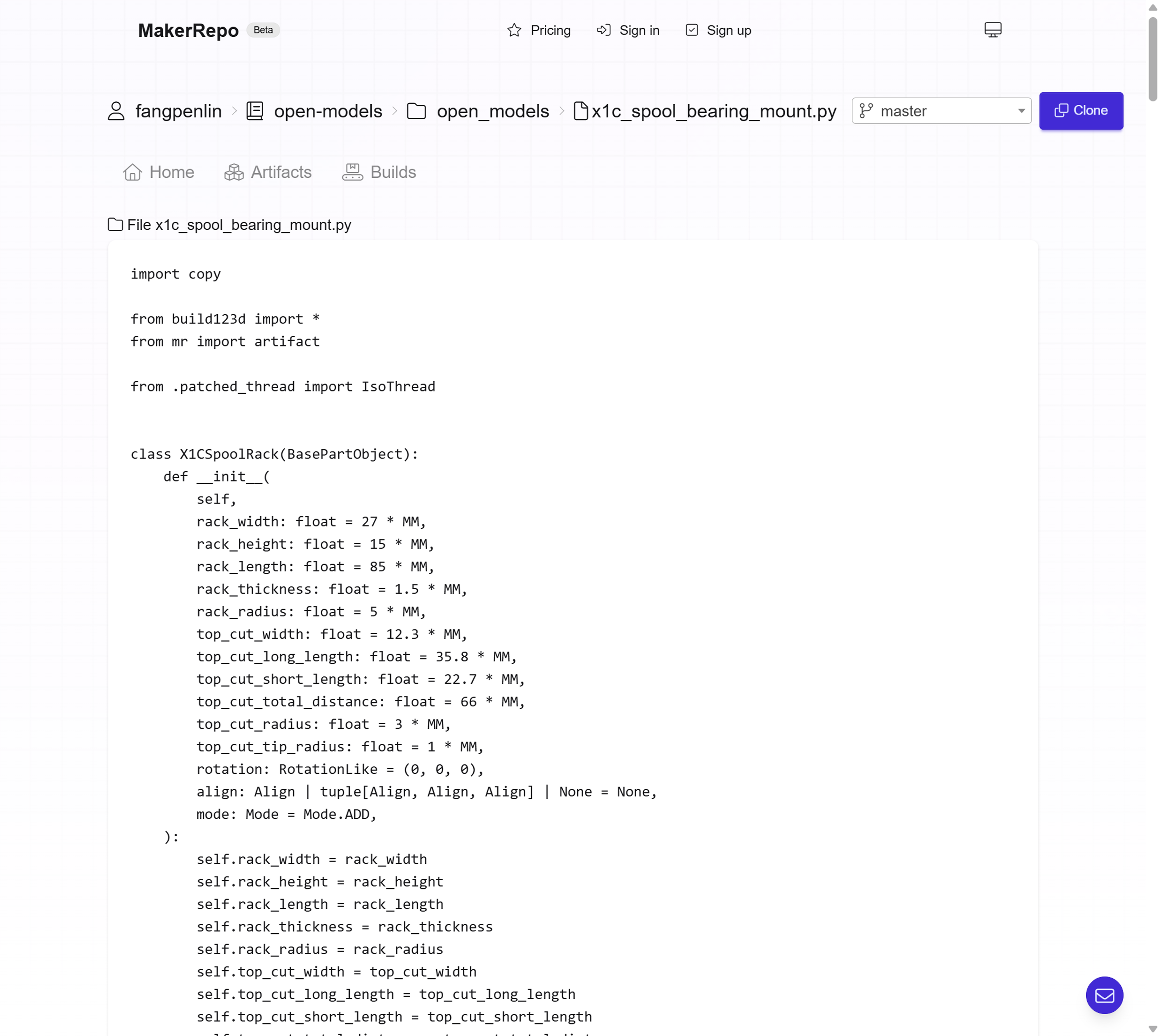

With that in mind, I spent the past few weeks building a prototype of a GitHub-like platform for manufacturing, called MakerRepo. Today I am very excited to announce that the project is now online and has entered the beta testing phase for the public. 😄🎉